What is an integrated circuit board?

What is an Integrated Circuit Board?

I. Introduction

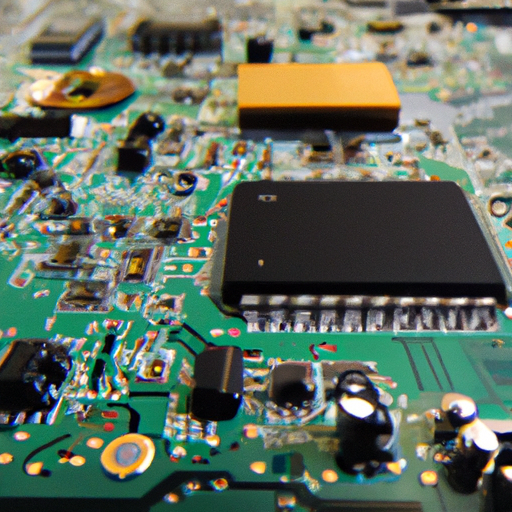

In the realm of modern electronics, the integrated circuit board (ICB) stands as a cornerstone of innovation and functionality. An integrated circuit board is a sophisticated assembly that combines multiple electronic components, including integrated circuits (ICs), resistors, capacitors, and connectors, onto a single substrate. This technology has revolutionized the way electronic devices are designed and manufactured, enabling the miniaturization of components and enhancing performance across a wide array of applications. In this article, we will explore the historical background, components, design and manufacturing processes, applications, advantages, challenges, and future trends of integrated circuit boards.

II. Historical Background

A. Evolution of Circuit Boards

The journey of circuit boards began with the advent of early electronic components in the mid-20th century. Initially, electronic devices were built using discrete components, which were bulky and required extensive wiring. The introduction of printed circuit boards (PCBs) in the 1950s marked a significant turning point. PCBs allowed for the efficient arrangement of components on a flat surface, reducing the size and complexity of electronic devices.

B. Introduction of Integrated Circuits (ICs)

The development of integrated circuits in the late 1950s further transformed the landscape of electronics. ICs enabled multiple transistors and other components to be fabricated onto a single chip, drastically reducing size and power consumption while increasing reliability. This innovation paved the way for the merging of PCBs and ICs into what we now refer to as integrated circuit boards.

C. The Merging of PCBs and ICs into Integrated Circuit Boards

The integration of ICs onto PCBs led to the creation of integrated circuit boards, which are now ubiquitous in virtually all electronic devices. This evolution has allowed for the development of complex systems that are compact, efficient, and capable of performing a multitude of functions.

III. Components of an Integrated Circuit Board

A. Integrated Circuits (ICs)

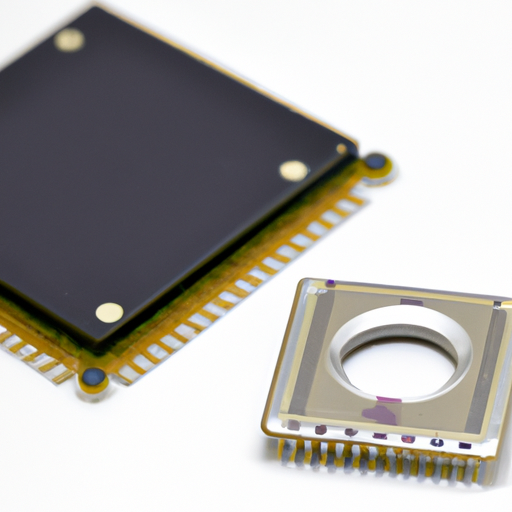

At the heart of an integrated circuit board are the integrated circuits themselves. An IC is a semiconductor device that contains a set of electronic components, such as transistors, diodes, and resistors, all embedded in a single chip. ICs can be categorized into three main types: analog, digital, and mixed-signal. Analog ICs process continuous signals, digital ICs handle discrete signals, and mixed-signal ICs combine both types.

B. Substrate Materials

The substrate material serves as the foundation for the integrated circuit board. Common materials include FR-4 (a fiberglass-reinforced epoxy laminate) and polyimide, each chosen for their unique properties. The substrate must provide mechanical support, electrical insulation, and thermal stability, making the choice of material critical to the board's performance.

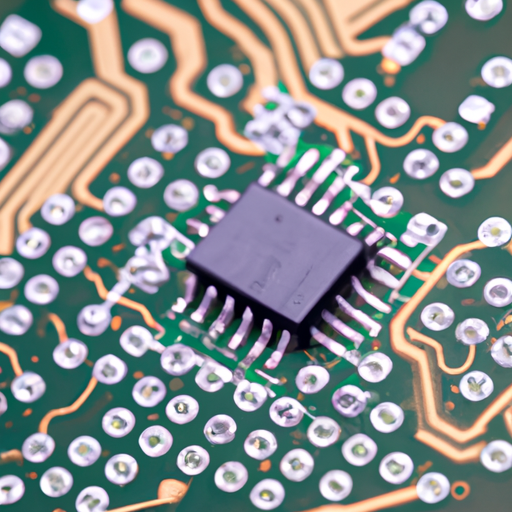

C. Conductive Pathways

Conductive pathways, typically made of copper, are essential for connecting the various components on the board. These copper traces are designed to carry electrical signals between ICs and other components. The design of these pathways is crucial, as it affects the board's overall performance, signal integrity, and electromagnetic compatibility.

D. Other Components

In addition to ICs, integrated circuit boards often include passive components such as resistors, capacitors, and inductors, which help regulate electrical signals. Connectors and interfaces are also integral to ICBs, allowing for communication with other devices and systems.

IV. Design and Manufacturing Process

A. Design Considerations

The design of an integrated circuit board involves several critical steps. The process begins with schematic design, where the electrical connections between components are mapped out. This is followed by layout design, where the physical arrangement of components and conductive pathways is determined. Effective design is essential for ensuring functionality, manufacturability, and reliability.

B. Manufacturing Techniques

The manufacturing of integrated circuit boards involves several advanced techniques. Photolithography is used to transfer the circuit design onto the substrate, while etching and plating processes create the conductive pathways. Assembly processes, such as soldering and surface mount technology, are employed to attach components to the board.

C. Testing and Quality Assurance

Once manufactured, integrated circuit boards undergo rigorous testing to ensure functionality and reliability. Functional testing verifies that the board operates as intended, while reliability testing assesses its performance under various conditions, including temperature fluctuations and mechanical stress.

V. Applications of Integrated Circuit Boards

A. Consumer Electronics

Integrated circuit boards are integral to consumer electronics, powering devices such as smartphones, tablets, and home appliances. Their compact design and high performance enable the development of multifunctional devices that enhance everyday life.

B. Industrial Applications

In industrial settings, integrated circuit boards play a crucial role in automation and control systems, as well as robotics. They facilitate precise control and monitoring of machinery, improving efficiency and productivity.

C. Medical Devices

The medical field has also benefited from integrated circuit boards, with applications in diagnostic equipment and wearable technology. These boards enable the development of advanced medical devices that provide real-time monitoring and data analysis.

D. Automotive Industry

In the automotive sector, integrated circuit boards are essential for engine control units and infotainment systems. They enhance vehicle performance, safety, and connectivity, contributing to the evolution of smart vehicles.

VI. Advantages of Integrated Circuit Boards

A. Miniaturization of Electronic Devices

One of the most significant advantages of integrated circuit boards is their ability to miniaturize electronic devices. By integrating multiple components onto a single board, manufacturers can create smaller, lighter, and more portable products.

B. Enhanced Performance and Efficiency

Integrated circuit boards improve the performance and efficiency of electronic devices. The close proximity of components reduces signal delay and power consumption, leading to faster and more efficient operation.

C. Cost-Effectiveness in Mass Production

The standardized manufacturing processes used for integrated circuit boards make them cost-effective for mass production. This efficiency allows manufacturers to produce high-quality products at lower costs, benefiting consumers.

D. Reliability and Durability

Integrated circuit boards are designed to be reliable and durable, capable of withstanding harsh environmental conditions. Their robust construction minimizes the risk of failure, ensuring long-term performance.

VII. Challenges and Future Trends

A. Challenges in Design and Manufacturing

Despite their advantages, integrated circuit boards face challenges in design and manufacturing. The increasing complexity of modern circuits requires advanced design tools and techniques. Additionally, thermal management issues can arise as components become more densely packed.

B. Future Trends in Integrated Circuit Board Technology

The future of integrated circuit boards is promising, with several trends emerging. Flexible and printed circuit boards are gaining traction, allowing for innovative designs and applications. Advances in materials and manufacturing techniques are also on the horizon, enhancing performance and sustainability. Furthermore, the integration of ICBs with emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) is expected to drive further innovation.

VIII. Conclusion

Integrated circuit boards are a fundamental component of modern electronics, enabling the development of compact, efficient, and reliable devices. Their evolution from early circuit boards to sophisticated ICBs has transformed the electronics industry, paving the way for advancements in various fields. As technology continues to evolve, integrated circuit boards will play a crucial role in shaping the future of electronics, driving innovation and enhancing our daily lives.

IX. References

For further reading on integrated circuit boards, consider exploring the following resources:

1. "Microelectronics: An Introduction to the Technology" by John D. Cressler

2. "Printed Circuit Board Design Techniques for EMC Compliance" by Mark I. Montrose

3. IEEE Xplore Digital Library for academic papers on circuit board technology

4. IPC (Association Connecting Electronics Industries) for industry standards and guidelines

This comprehensive overview of integrated circuit boards highlights their significance, components, and the future of this essential technology in electronics.